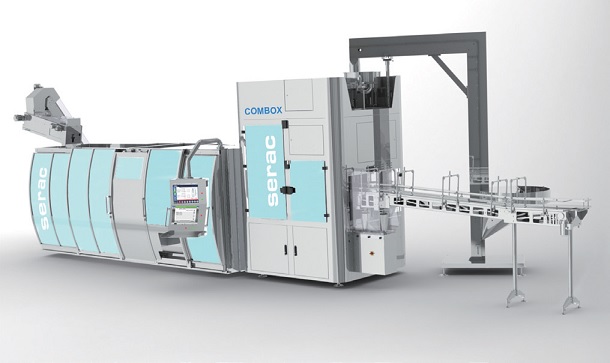

法國塞拉克推出用於乳製品的全新Combox H2F吹製灌裝密封方案

法國塞拉克推出用於乳製品的全新Combox H2F吹製灌裝密封方案

法國塞拉克 (SERAC) 集團在國際飲料及液體食品技術博覽會(Drinktec)上推出一種專門為乳製品包裝而設的全新超級潔淨吹製灌裝密封生產線,包裝速度低於每小時一萬兩千瓶。採用這種技術,在現場吹製灌裝牛奶的瓶子不再僅限於高頻率的包裝速度。

在塞拉克公司無菌包裝技術的啟發之下設計出一款超級潔淨牛奶包裝生產線

這種命名為Combox的一體式包裝新方案組合了一台適合於在製冷回路中銷售的乳製品衛生標準的H2F (Highly Hygienic Filler) 灌裝機。在該公司最新的無菌包裝創新技術的啟發之下,H2F灌裝機是為優化成本而設,以適合大部分工廠的需要。

大眾化的吹製/灌裝一體機

在包裝的綜合方案方面,現有可供中等規模的乳製品生產商選擇的設備範圍很小,盒式包裝只適合於較低的包裝頻率,而吹製灌裝密封生產線的設備對於他們的需要來說,規模往往都很大。而塞拉克提供的Combox H2F是一種適合這些廠商需要的方案,使他們可以受益於現場吹製玻璃包裝器皿的好處。

PET吹製機與充填劑量控制裝置組成旋轉式包裝機

塞拉克集團擁有四十年的灌裝經驗,在包裝多樣化的精神推動之下,將PET玻璃瓶吹製技術組合引入包裝一體化方案當中,而這種設計是為了適合於旋轉式包裝機的充填劑量控制。該公司提出的吹製灌裝密封方案是以一種間距調整技術為基礎,這項技術已註冊專利,可以使生產線從玻璃吹製機的時序操作流程過渡到旋轉灌裝機的連續操作流程。

Combox H2F方案是為迎合新興市場PET瓶裝乳製品生產廠商的需要設計的,也可以用於生產量不大,但是產品附加值比較高的細分市場產品,應能在法國和其他國家引起客戶的關注。

該款生產線將在塞拉克公司在國際飲料及液體食品技術博覽會第A6展廳334展臺進行演示。

有關塞拉克集團(SERAC GROUP):

塞拉克集團設計、組裝並為業界提供乳製品、食用油、家居和個人衛生產品的包裝方案 (包裝機和完整的包裝生產線),以及一些週邊市場的設備。目前,塞拉克開設了十間辦事處,分別位於法國、巴西、美國、馬來西亞、印尼、俄國、日本、中國、西班牙、英國。還有六間生產工廠,分別位於法國 (三間)、巴西 (一間)、美國 (一間) 和馬來西亞 (一間)。塞拉克公司在全世界一百多個國家已安裝超過五千個包裝方案。

塞拉克公司的策略是要做到與競爭夥伴不同,開發有商業和工業前途,國際應用廣泛,能夠適用於各個市場的獨特模式,從而使客戶在該公司的產品中獲得優勢。

有關產品詳情,請聯繫:

Serac Packaging Equipment (LANGFANG) Co., Ltd.

Demi LIU Na

(86) 139 0109 5481

demi.liu@serac.com.cn

-----------------------------

Serac unveils Combox H2F, its new blow molding-filling-capping solution for the dairy market

COMBOX H2F : blow molding-filling-capping solution for the dairy market

The Serac Group unveils its new ultra-clean blow molding- filling- capping line at the Drinktec tradeshow. It is specifically designed for dairy bottles production below 12,000 bottles per hour. This innovation opens new perspectives for lower speed dairy products manufacturers, as they are able to blow mold bottles in house.

Ultra-clean filling backed by Serac’s 40 years experience in aseptic packaging

The fully integrated solution, branded Combox, incorporates the H2F (Highly Hygienic) filler that meets the hygiene requirements of cold chain dairy products. The focuses in the machine design phase were to integrate the company’s latest aseptic filling innovations and to control cost. As a result its competitive advantages can be acquired at a reasonable price.

An affordable blow molding and filling solution

Mid-sized dairy products manufacturers had until now a limited choice of integrated packaging lines : on one side cartons for low speed packaging, on the other side complete blow molding-filling-capping lines that were often oversized. With the Combox H2F, Serac gives them the appropriate equipment to blow mold in house.

PET blow molding combined with rotary weight filling machines

With over 40 years experience in filling, the Serac group provides the capability to integrate PET blow molding with any of its fillers-cappers. A unique and patented transfer system converts sequential motion of the linear blower into a continuous motion which adapts to any Serac rotary filler.

The Combox H2F should rapidly penetrate the dairy market, as it answers the needs of developing countries using PET, as well as the low volume and high value-added product segments.

The Combox H2F will be on display at Drinktec in September 2013 on the Serac booth, number 334, hall A6.

About Serac group

Serac group designs, assembles and provides packaging solutions (machines and lines) to industrial companies and end-users, mainly in dairy products, edible oil and home and personal care products.

It comprises 10 commercial offices located in France, Brazil, USA, Malaysia, Indonesia, Russia, Japan, China, Spain, England and 6 factories in France (3), Brazil (1), U.S.A. (1) and Malaysia (1).

Serac has installed more than 5 000 packaging solutions in over 100 countries.Serac’s strategy is to differentiate ourselves from competitors by taking advantage of what makes us shine: a unique model, structured around a highly international commercial and industrial presence in all markets.

For more details, Please contact

Serac Packaging Equipment (LANGFANG) Co., Ltd.

Demi LIU Na

Tel: (86) 139 0109 5481

Email: demi.liu@serac.com.cn