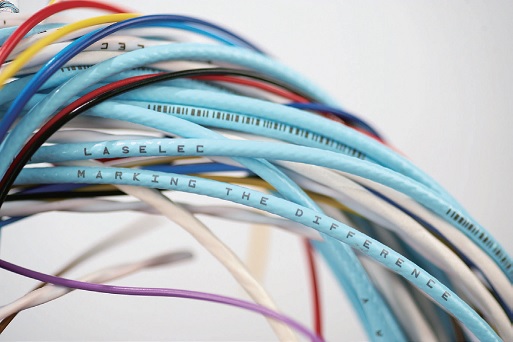

LASELEC鐳射電纜標記列印又出新工藝

創新、再創新 - LASELEC鐳射電纜標記列印又出新工藝

繼推出利用鐳射為鋁質電纜列印標記的新工藝之後,法國拉塞萊克公司(LASELEC)不斷追求改進,最近又開發了一種新的裝置,可以節約電纜的剪切殘段。基於對創新的持續追求,拉塞萊克公司已躋身于世界航空和工業電纜標記列印領域的領先行列。正因為該公司的高新技術創新特徵,二零一二年LASELEC被選中在法國跨部聯合基金(FUI)的框架之內參與了「維蘇威」合作研究計畫,計畫實施受到「歐洲地區發展基金」(ERDF) 全程支援。

在生產新型號電纜時,開頭總會有一米左右的電纜線是不能使用的。由於航空電纜價格高昂,如果生產量很大,由此導致的成本浪費就很大。LASELEC開發的自動進給系統可減少這一剪切殘段造成的損失。裝備了這一系統的ULYS Modena電纜標記印表機剪切殘段的長度只有四到十二釐米。該裝置可以用於單軸放線機,也可用於多軸放線機。由於LASELEC公司的「相容改進」研發策略,客戶已在使用中的各種型號的ULYS Modena機器均可添加這一裝置。

MIHAILA Modena系列電纜標記印表機能夠滿足客戶不同層級的需求。如果生產所需的列印頻率不高,入門級的ULYS 110標記印表機就足夠使用;而根據需要亦可選擇至ULYS 990的最高生產效率。MIHAILA Modena和MRO 200鐳射標記印表機用電腦控制,是完全自動化的標記印表機並擁有品質追溯的功能。這些機器使用簡單、性能優越。除了這兩個系列之外、 最近該公司又在推出新的型號。

紫外線鐳射電纜標識技術保證了列印標記永不褪色,而且對電纜的絕緣不會造成任何損害,目前在民用和軍用專案中經常使用。航空器的維護、改造和修理中心也對這種技術越來越關注。MRO 200標記印表機就是拉塞萊克公司專門為適應這些部門的需要而開發的。該系列的標記印表機專門用於中小批量和單根電纜的標記列印,可用於對電纜標記的修改,也可適用于很多小批量生產的車間。該系列標記印表機的電纜放線和切割系統結構堅固,品質牢靠,能夠保證電纜線絕緣的完整性。

紫外線標記直接列印的另一個根本性的優越之處,是減輕了電纜的重量,從而也就減少了機載設備的總重量,使使用者可以降低能源成本。在航空器的製造當中,直接標記列印已經漸漸代替了標記套管的使用。高檔工業車輛、高檔汽車、賽車等的佈線也因其特殊要求而採用LASELEC的電纜標記印表機。某些國家的鐵路工業也開始採用這種標記列印裝置,比如龐巴迪運輸公司(BOMBARDIER Transportation)。

拉塞萊克(LASELEC)公司簡介:

拉塞萊克公司生產的電纜標記印表機在世界上為航空器製造商所廣泛採用,例如阿古斯塔韋斯特蘭飛機公司,空中客車公司,BAE系統公司,貝爾直升機公司,波音公司,龐巴迪公司,賽斯那飛機公司,昌河飛機製造公司,歐洲宇航防務集團,巴西航空工業公司,歐洲直升機公司,灣流飛機公司,印度HAL集團公司,吉斯通直升飛機公司,洛克希德馬丁公司,米格公司,諾斯羅普格魯曼公司,上海飛機製造公司,瀋陽飛機製造公司和西科斯基飛機公司等等。拉塞萊克公司80%的營業額來自于國際銷售。該公司對亞洲和美洲寄予厚望。拉塞萊克公司二零零四年在印度設立代表機構,現在印度最大的生產商已經裝備了拉塞萊克的標記印表機。二零一一年和二零一二年,HAL公司集團及其分包商(尤其是ROSSEL集團以及法國和美國的聯合集團AMPHENOL-SEFEE公司)都購買了最新的標記列印裝置。在日本,拉塞萊克公司二零一一年設立了一個新的客戶服務中心。日本若干大集團都選擇了該公司的產品,如富士重工、JAMCO、三菱重工、SANYU、 住友等。

拉塞萊克公司還打算在中國設立客戶支援機構以及零部件備品倉庫。拉塞萊克公司已在中國擁有很多客戶,其中包括諾典科技公司、上海飛機公司、昌河飛機製造公司、瀋陽飛機製造公司,等等。

另外,由於其產品和客戶服務的優良品質,拉塞萊克公司在美洲大陸也有很好的市場地位。該公司在達拉斯和克雷塔羅設立有辦事處。拉塞萊克公司於二零一三年將會在數個重要國際展會上亮相,尤其是法國布林熱航空展、莫斯科國際航空航太展(MAKS),NBAA航空展會以及在美國舉辦的Heli Expo展會。

如需更多資訊可聯繫:

拉塞萊克公司(LASELEC)

商務經理Marie-Line Laval女士

電話:+33 (0) 582 950 555

電郵: info@laselec.com

公司網站: www.laselec.com

---------------------------------------------------

LASELEC develops system to reduce wire waste in industry

LASELEC, a leader in the UV-laser industry, has designed a new wire-marking system that will reduce wire waste in industry, especially aerospace. The company has developed a method that uses ULYS Modena wire markers and an automatic feeding system to reduce waste from 1 metre to between 4 and 12 centimetres.

Each time production begins on a new type of wire, up to a metre is wasted, which can lead to substantial costs due to the price of aeronautical wire, for example. LASELEC, a worldwide leader in the UV-laser industry, has developed a method that can reduce such waste to a length of between 4 and 12cm, using ULYS Modena UV-laser wire markers and automatic feeding.

The system can be mounted on both single-spool and multi-spool dereelers and, thanks to LASELEC’s innovative design; the system can also be retrofitted on all ULYS Modena machines that are already installed.

Using UV lasers to identify electric wiring is currently a method in widespread use in both military and civilian projects, as it is a process that provides indelible marking without damaging the insulation, thanks to the machine’s robust and reliable wire dereeling and cutting system.

The ULYS Modena UV-laser range perfectly meets all wire-marking requirements, from the ULYS 110, which is an entry-level machine that is suitable for low-production rates, to the ULYS 990, which has unmatched productivity.

Entities involved in modification, maintenance and repair of aircraft are showing growing interest in this technology. The MRO 200 was developed by LASELEC specifically to meet the needs of such aerospace companies. Devoted to small and medium production runs and to unit-by-unit production, this range of markers is used in workshops producing small runs and can be used for rework.

The French-based company’s computer-controlled laser cable markers are easy to operate, reliable and efficient. The marking ranges are constantly evolving and have had new models added this year.

A key benefit of direct UV-laser marking is a reduction in the wiring weight, which subsequently reduces the weight of the wire-equipped devices, lowering users’ energy costs. Such wire marking is gradually replacing sleeving in the aeronautics industry, and LASELEC equipment is used by all of the main aircraft manufacturers, including Airbus, BAE Systems, Boeing, EADS, Embraer, Eurocopter, Northrop Grumman, and Sikorsky.

The rail industry has also begun using LASELEC equipment, including Canadian rail specialist Bombardier Transportation. Similarly, workshops for industrial vehicles, as well as those for upscale, competition and rally vehicles, feature such equipment, which is specifically suited to their particular requirements.

In 2012, LASELEC began to take part in a collaborative R&D project, VESUVE, which aims to improve considerably the productivity of aeronautical-cable production by developing the laser solutions of the future. VESUVE will take place within the framework of the Fonds Unique Interministériel (FUI, France’s Inter-ministerial Single Fund) and will be supported throughout by the European Regional Development Fund (ERDF). The project was selected by ERDF thanks to its innovative approach to wire waste, along with the business that it will generate.

LASELEC makes over 80% of its turnover outside France. Since 2004, the company has had great success in India, signing contracts with HAL Group and its subcontractors, including ROSSEL and AMPHENOL-SEFEE Group, in 2011 and 2012.

The reliability and quality of LASELEC products and its customer service are acknowledged worldwide, especially in Japan where the company founded a support centre in 2011 and established relationships with FHI, JAMCO, MHI and SANYU.

Moreover, LASELEC is successful in China, where it has a range of customers, including Changhe Aircraft, Lode Technology and Shanghai Aircraft. LASELEC is also well established in America, thanks to the Customer Support Service provided by LASELEC Inc. from its offices in Dallas and Queretaro.

About LASELEC

LASELEC is a French-based specialist in laser technology with over 20 years’ experience. The company provides UV-laser systems for wire and cable marking.The company will attend the following trade shows in 2013:

- Paris Air Show (France) from 17 to 23 June 2013.

- MAKS Air Show (Russia) from 13 to 18 August 2013.

- NBAA (USA) in 2013.

- HELI-EXPO (USA) from 4 to 7 March 2013.For further information about LASELEC, please go to: www.laselec.com